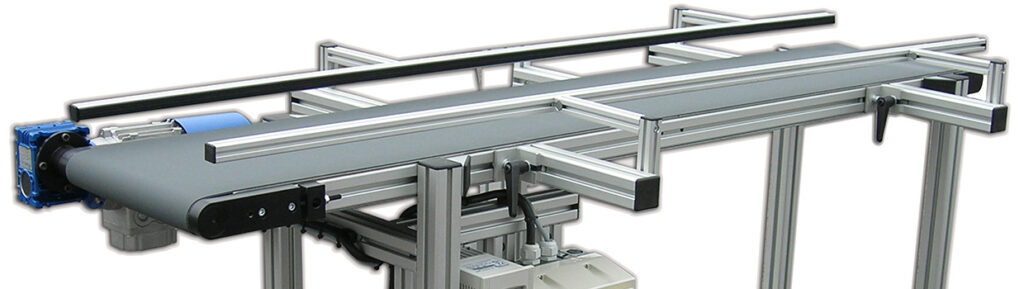

Industrial vacuum conveying

Overview

The Piab piFLOW®i is a conveyor widely used in the general industry and sometimes in the chemical industry. It has a high throughput performance as well as a small foot print. This conveyor is often used as an alternative to mechanical conveyors when there is a requirement for dust-free conveying or low maintenance. Another advantage is that the pump is based on COAX® technology which is the most energy-efficient way to produce the vacuum. Capacity up to 7,5 tons/h. The general industry often handles abrasive powders that require specially designed equipment. Our conveyors are designed with a Stainless Steel body (ASTM 304) to resist the wear of parts. Piab conveyors are ATEX Dust certified. piFLOW®p and piFLOW®t are ATEX Gas certified. All conveyors are available with either an ejector driven vacuum pump or with a mechanical pump.

Features

- A cost-effective solution for any industry, that wishes to automate the manual material handling process for improved throughput.

- The Piab COAX® Technology, the most energy-efficient way to produce the vacuum, is used in the pump.

- ATEX Dust certified.

- Steel quality ASTM 304 (stainless steel), pickled surface treatment.

- Antistatic filter and seals.

- Automatic filter cleaning.

Downloads

News

4 fascinating facts about hydraulics

Hydraulics may be one of the most important inventions in the modern world. They are used in a variety of…

New range of products Machine Building

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Elementum…

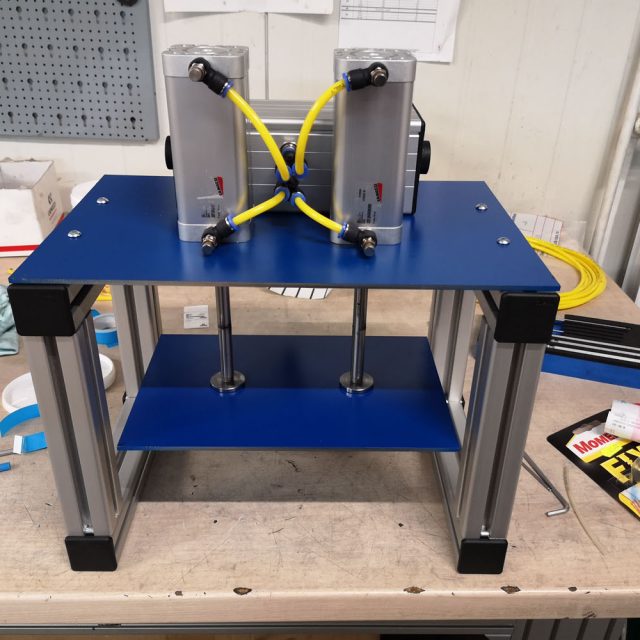

HOW TO OPTIMIZE THE PACKAGING PROCESS?

Application Making a pneumatically operated press in order to hermetically close plastic containers. Problem Description In the process of producing…

HOW DID WE TEST THE KENOS GRIPPER?

RISKS During time of use there is the possibility of clogging the grippers with PVC residues resulting from the cutting…